The field of industrial robotics is continuously evolving, showcasing remarkable innovations that reshape industries and improve productivity. Understanding these advancements is crucial for companies aiming to stay competitive.

Emergence of Collaborative Robots

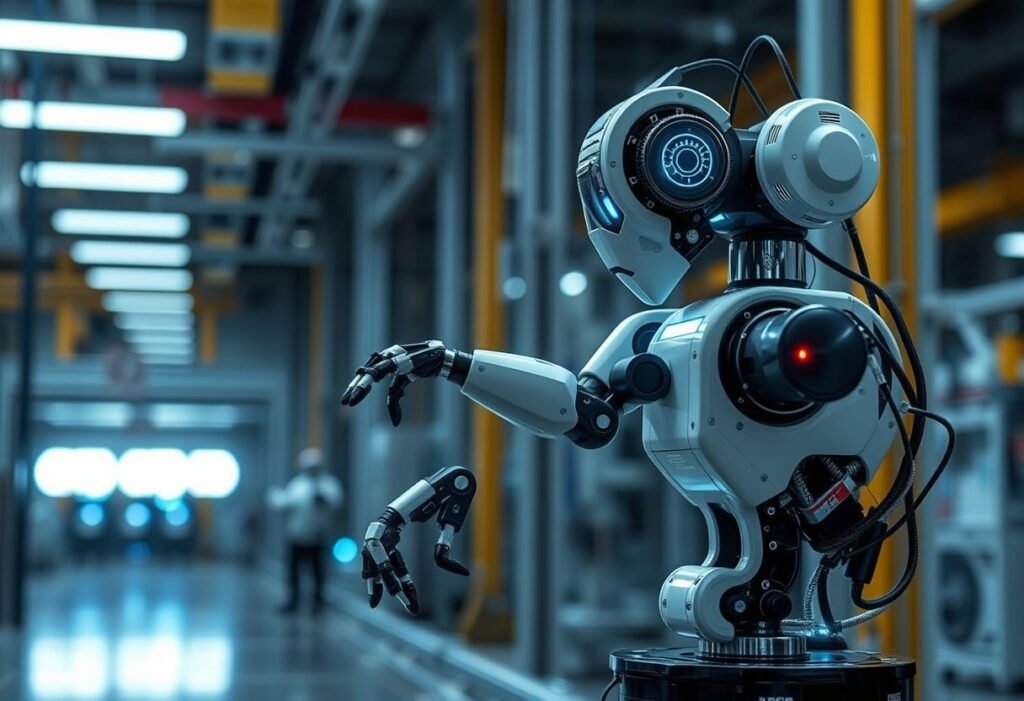

Collaborative robots, or cobots, are designed to work alongside humans, enhancing the workplace by promoting safety and efficiency. Unlike traditional robots, which often operate in isolation, cobots can adapt to human presence and interact directly, facilitating smoother workflows and reducing the risk of workplace accidents. They are equipped with advanced sensors and AI, allowing them to recognize and adjust actions based on human movements. This innovation not only boosts productivity but also makes robotics more accessible to smaller businesses.

Artificial Intelligence Integration

The integration of artificial intelligence in robotics has led to significant breakthroughs. AI enhances robots’ decision-making capabilities, allowing them to optimize operations in real time. In manufacturing settings, AI-enabled robots can analyze data from various processes, learning from past experiences to improve efficiency and reduce waste. This type of innovation streamlines production lines and fosters a culture of continual improvement, elevating overall productivity levels.

Advanced Sensor Technology

Modern industrial robots utilize advanced sensor technology to interact more effectively with their environment. Sensors such as LIDAR and vision systems enable robots to perform complex tasks by providing precise data about their surroundings. This technological enhancement allows robots to navigate dynamic work environments autonomously, ensuring they can adapt to changes without human intervention. As a result, these robots can perform a wider range of applications, from assembly to quality control.

Remote Operation and Monitoring

Another significant innovation is the ability to remotely operate and monitor industrial robots. This capability is increasingly important as companies seek to maximize productivity while ensuring safety amid challenging conditions. Through remote monitoring technologies and the Internet of Things (IoT), operators can manage robots from a distance, reducing the need for on-site personnel. This not only increases efficiency but also allows for quick response to operational issues.

Edge Computing in Robotics

Edge computing plays a crucial role in industrial robotics by allowing data processing to happen closer to where it is generated. This innovation decreases latency and improves response times crucial for real-time applications. By processing data on-site, robots can make immediate decisions without reliance on cloud computing, fostering faster and more efficient operations. The integration of edge computing also enhances data security, as sensitive information remains within local networks.

Green Robotics and Sustainability

With the growing emphasis on sustainability, innovations in green robotics are emerging as a key focus. Many manufacturers are designing robots that use renewable energy sources or are built from eco-friendly materials. These advancements not only lessen environmental impact but also help companies meet regulatory requirements and public sustainability goals. As industries increasingly integrate green practices, the demand for sustainable robotics is expected to rise significantly.

Disclaimer: This article is for informational purposes only and is not intended as professional advice.