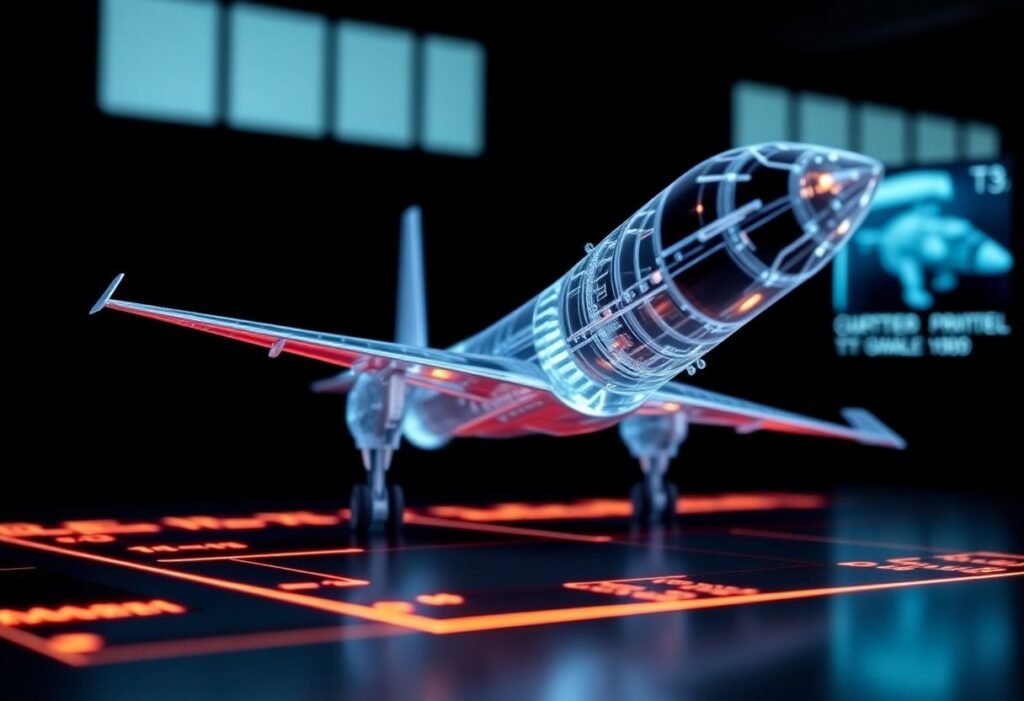

As innovation accelerates across multiple sectors, the aerospace industry stands at the forefront, embracing technologically advanced solutions. The evolution of 3D printing technology has revolutionized aircraft manufacturing and maintenance processes, leading to enhanced efficiency and cost-effectiveness.

The Rise of 3D Printing in Aerospace

The adoption of 3D printing in the aerospace industry represents a significant advance in production techniques. Initially utilized for prototyping, the technology has evolved to produce complex components from various materials, including metal and carbon composites. This innovation enables manufacturers to create lightweight parts that offer improved aerodynamics and fuel efficiency. The ability to customize components on demand also drives innovation in design, allowing engineers to explore intricate geometries previously thought impractical. Major aerospace companies are now incorporating additive manufacturing to optimize their supply chains, reduce waste, and improve turnaround times.

Streamlining Supply Chains

3D printing has a profound impact on the supply chains within the aerospace industry. Traditional manufacturing often involves long lead times and high inventory costs. However, with additive manufacturing, parts can be produced on demand, significantly reducing the need for large stockpiles. This flexibility allows companies to respond swiftly to changing market demands, ensuring that they can meet customer needs without incurring excess production costs. Furthermore, producing parts locally reduces transportation times and carbon footprint, contributing to sustainability goals.

Enhancing Design Capabilities

The design capabilities offered by 3D printing are changing the landscape of aerospace engineering. Engineers can create complex geometries and integrated designs that were previously not feasible with conventional manufacturing methods. This freedom of design allows for the development of lighter, stronger components that enhance overall aircraft performance. Notably, parts can be designed with built-in features, reducing the need for multiple assembly processes. The innovation exemplified by 3D printed structural components represents a paradigm shift in how aircraft parts are conceived and manufactured.

Reducing Weight and Improving Efficiency

One of the significant advantages of incorporating 3D printing in aerospace is the weight reduction of components. Lighter aircraft require less fuel, leading to lower operational costs and a reduced environmental impact. The aerospace sector continuously seeks ways to enhance energy efficiency, and additive manufacturing contributes significantly to this goal. By allowing for the production of lightweight yet robust parts, the industry can improve fuel economy, thereby promoting a more sustainable approach to air travel.

Real-World Applications of 3D Printing

The integration of 3D printing in the aerospace industry has already yielded tangible results. Companies like Boeing and Airbus have developed and flown aircraft that incorporate additively manufactured components. From engine parts to cabin interiors, various applications showcase the potential of this technology. For instance, the production of intricate fuel nozzles via 3D printing has showcased significant efficiency improvements, allowing for more consistent part performance and lower maintenance requirements.

The Future of 3D Printing in Aerospace

Looking ahead, the future of 3D printing in the aerospace industry is poised for even greater innovation. As materials science advances and hybrid manufacturing techniques evolve, the capabilities of additive manufacturing will expand. The industry is expected to increase adoption rates, driven by ongoing research and development. Collaboration between aerospace companies and technology innovators will likely lead to breakthroughs that optimize production processes and enhance the performance of aircraft. 3D printing is rapidly changing the landscape of aerospace manufacturing, and its potential remains vast.

Disclaimer: The information provided in this article is intended for informational purposes only and does not constitute professional advice.