The evolution of 3D printing technology has paved the way for innovative materials that transform various industries. These new materials are not just enhancing capabilities but also reimagining applications across sectors such as healthcare, aerospace, and consumer products.

Advancements in Biocompatible Materials

One significant innovation in the realm of 3D printing is the development of biocompatible materials. These materials are designed to interact safely with biological systems, making them ideal for applications in the medical field. For instance, biocompatible polymers are being utilized in the manufacturing of customized prosthetics and implants. This advancement not only increases the effectiveness of medical devices but also improves patient comfort and acceptance. By utilizing these advanced materials, healthcare professionals can create solutions that are tailored to individual needs, ultimately enhancing the quality of care.

Metals and Alloys for Enhanced Durability

The introduction of new metal alloys specifically designed for additive manufacturing has revolutionized the way we approach design and production. These metals offer enhanced durability and resistance to extreme conditions, making them suitable for industries such as aerospace and automotive. By leveraging these materials, engineers can design components that are not only lighter but also stronger, leading to improved performance and longevity. The ability to 3D print complex geometries from these advanced metals opens up a new realm of possibilities, allowing for innovation that was previously unattainable.

Eco-Friendly Materials for Sustainable Production

As sustainability becomes a priority, the development of eco-friendly materials for 3D printing is gaining traction. These materials are derived from renewable sources and designed to minimize environmental impact. Innovations such as biodegradable filaments made from cornstarch or recycled plastics are paving the way for greener manufacturing practices. By adopting these sustainable materials, companies can not only reduce their carbon footprint but can also appeal to a growing consumer base that prioritizes environmental responsibility in their purchasing decisions.

High-Performance Thermoplastics

Another significant development in 3D printing technology is the creation of high-performance thermoplastics. These materials are characterized by their strength, heat resistance, and flexibility, making them ideal for demanding applications. Industries such as aerospace, automotive, and electronics are increasingly incorporating these thermoplastics into their products. The ability to 3D print complex structures from these materials not only streamlines production but also helps in reducing waste, as traditional manufacturing methods often involve extensive material waste.

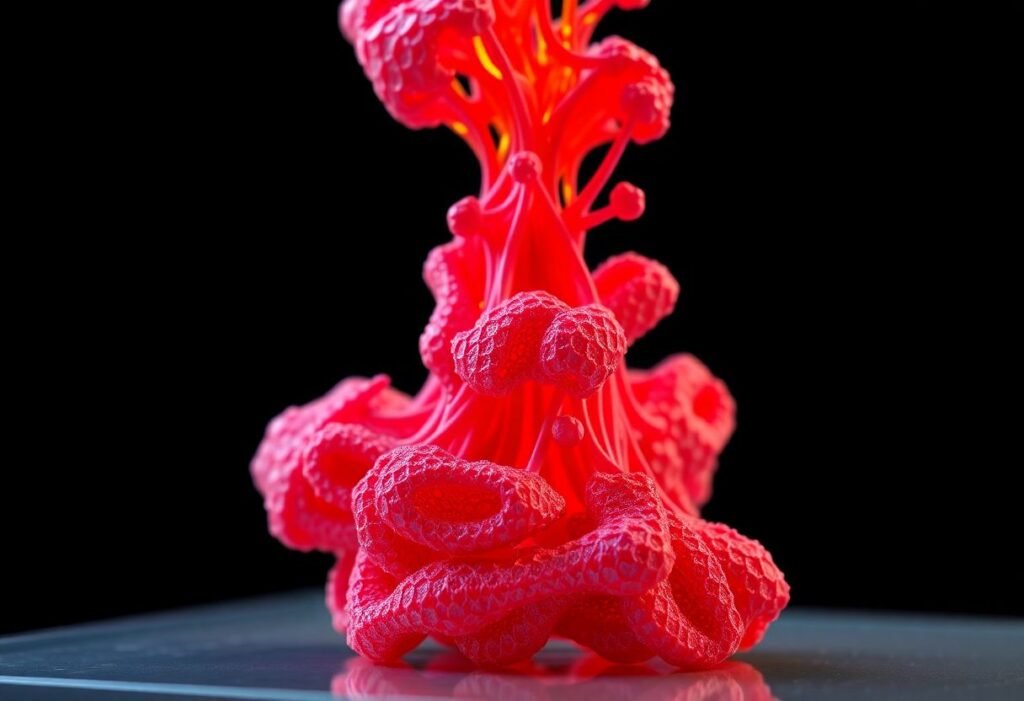

Composite Materials for Improved Functionality

The integration of composite materials into 3D printing processes offers significant advantages in terms of functionality and performance. By combining materials, such as carbon fiber reinforced polymers, manufacturers can achieve customized mechanical properties that cater to specific applications. These composites can be tailored for lightweight, yet highly durable parts essential in industries like sports equipment and automotive components. The versatility of composite materials enhances design freedom and encourages innovation across various sectors.

Future Trends in 3D Printing Materials

Looking ahead, the future of 3D printing technology will likely see an influx of novel materials designed for specialized applications. From smart materials that respond to environmental changes to high-performance ceramics, the ongoing research will continue to challenge the limits of what is possible in additive manufacturing. As the industry evolves, staying informed about these material innovations will be crucial for companies aiming to maintain competitiveness in a fast-paced landscape. Embracing these advancements can lead to new opportunities and innovative solutions across diverse fields.

This article is for informational purposes only and should not be considered as professional advice.