This innovative article discusses groundbreaking techniques developed in Austria that revolutionize material joining methods. By utilizing sound waves and 3D printing, these techniques not only eliminate the need for traditional adhesives but also enable the creation of exceptionally strong bonds between different materials.

The Future of Bonding: Sound and 3D Printing

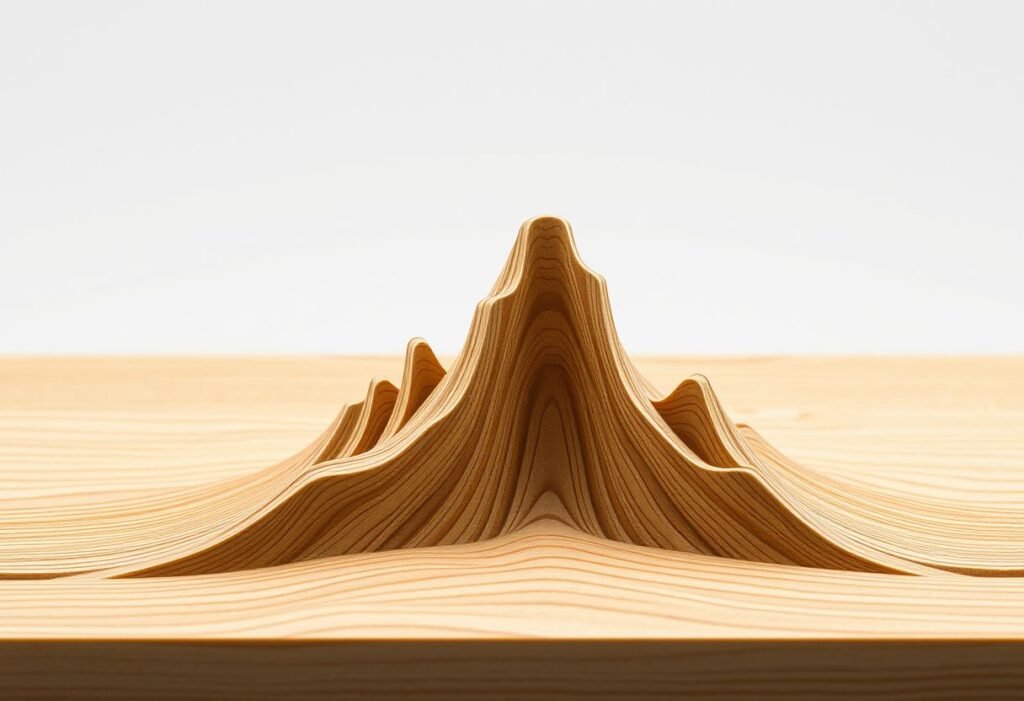

Recent advancements in material science have led to two innovative methods for joining dissimilar materials, specifically wood and metal, without the use of any adhesives. Researchers at an Austrian university have pioneered these techniques, which leverage ultrasonic waves to generate heat at the microscopic level. This heat facilitates the joining of materials at their pore level, allowing for a bond that is significantly stronger than those achieved through conventional means. This technology not only paves the way for environmentally friendly manufacturing processes but also enhances the structural integrity of products in various applications.

Advantages of Adhesive-Free Technology

The elimination of adhesives presents numerous benefits for both manufacturers and consumers. Traditional adhesives can weaken the bond over time due to exposure to moisture, heat, or chemical interactions. In contrast, the ultrasonic joining methods developed in Austria create durable connections that are resistant to these adverse conditions. Furthermore, this process has the potential to reduce production costs and minimize waste, making it an attractive alternative for the future of manufacturing.

Applications Across Industries

The ability to join materials like wood and metal opens a plethora of opportunities across various industries. From construction to automotive, this technology can be applied to create more robust and reliable products. For example, in the construction sector, the integration of strong wood-metal joints can lead to the development of sustainable and longer-lasting structures. Similarly, in the automotive industry, this method could enhance the performance and safety of vehicles by providing stronger joints in critical components.

The Role of 3D Printing in Material Joining

3D printing plays a crucial role in the success of these new bonding techniques. By enabling precise layer-by-layer construction, 3D printing complements the ultrasonic joining process. This synergy allows manufacturers to have greater control over the design and quality of their products. Additionally, the ability to create complex geometries facilitates the joining of diverse materials in ways that were previously unattainable, pushing the boundaries of modern manufacturing.

Environmental Implications of New Joining Methods

The shift towards adhesive-free joining techniques carries significant environmental implications. Conventional adhesives often contain harmful chemicals that can jeopardize both human health and the environment. By using sound waves instead of harmful substances, this new joining technology aligns with sustainability goals, promoting greener manufacturing practices. Reduced reliance on caustic adhesives can lead to less waste, improved recyclability of materials, and a smaller carbon footprint within the manufacturing landscape.

Future Prospects and Enhancements

Looking ahead, the potential for further enhancements in ultrasonic joining is immense. Researchers continue to explore additional applications and refinements in the process, aiming to expand its viability across more materials and industries. Additionally, ongoing advancements in 3D printing technology will likely enhance the compatibility of these joining techniques with diverse substrates, leading to unprecedented combinations in product design and functionality. The future promises not only an evolution in how we join materials but also a shift towards more sustainable, efficient manufacturing solutions.