The recent breakthrough from Stanford University heralds a significant advancement in the field of lithium extraction. As the demand for electric vehicles and renewable energy sources continues to rise, finding efficient and sustainable methods for lithium production is becoming increasingly critical. This new technique not only offers the potential for lower costs but also promotes cleaner extraction practices, aligning with global sustainability goals.

Revolutionizing Lithium Extraction Techniques

The ever-growing demand for lithium, a key component in rechargeable batteries, has prompted researchers to seek more efficient extraction methods. Stanford’s latest innovation proposes a technique that could reduce the costs of lithium extraction by up to 50%. This advancement could drastically affect the economics of lithium production, making it more accessible to manufacturers and potentially lowering the prices of electric vehicles (EVs) and other lithium-powered devices.

The Environmental Impact of Traditional Methods

Traditional lithium extraction methods are often detrimental to the environment, involving extensive mining operations that can disrupt ecosystems and deplete vital water resources. The Stanford team’s method aims to mitigate these adverse effects by utilizing more sustainable practices that limit the environmental footprint. By focusing on cleaner extraction techniques, this innovation represents a significant step towards a more sustainable future in battery production.

How the New Method Works

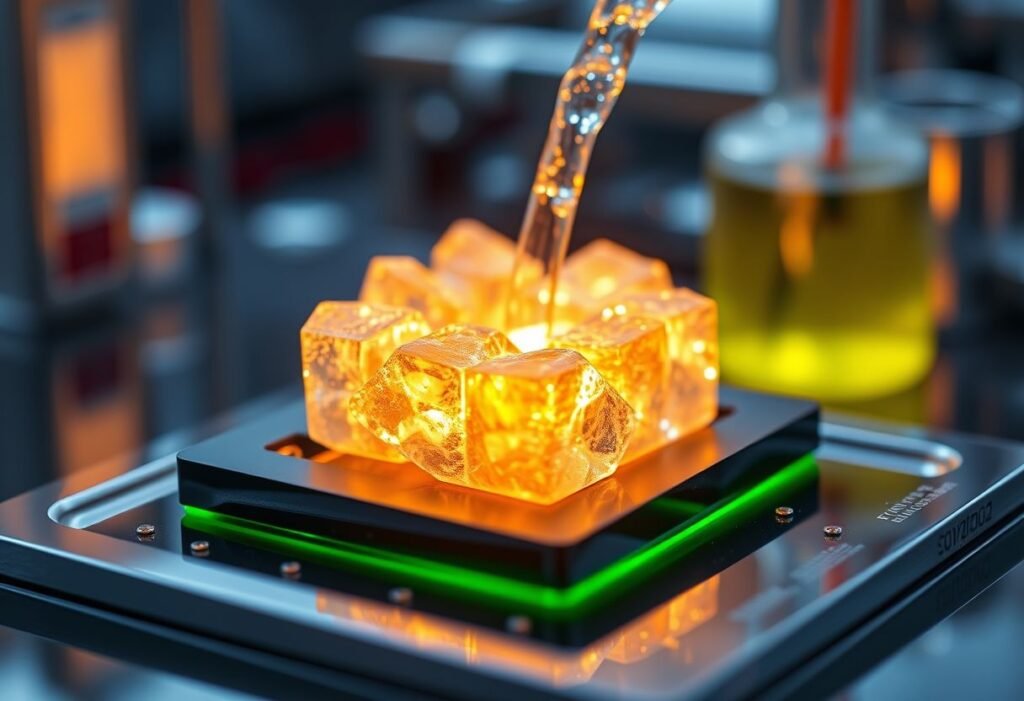

The breakthrough technique developed by Stanford researchers involves using a novel chemical process that separates lithium from brine in a more efficient manner. By enhancing the existing methods of lithium extraction, the researchers have utilized new materials that allow for faster recovery times and reduced energy requirements. This process not only decreases the ecological impact but also enhances the yield of lithium from local brine sources.

Comparing Costs and Benefits

Cost efficiency is a prime factor driving innovations in lithium extraction. Reducing the extraction costs by 50% could enable manufacturers to produce batteries and electric vehicles at prices that are more appealing to consumers. Additionally, the affordability of clean lithium extraction could promote wider adoption of green technologies, contributing to the transition towards a more sustainable society. The financial benefits, combined with environmental sustainability, create a compelling case for adopting this new method.

The Future of Lithium Production

As researchers continue to refine this innovative extraction technique, the future of lithium production looks promising. With a focus on sustainability and cost reduction, this advancement may lead to an influx of cleaner, more affordable lithium on the market. The implications could be profound, affecting everything from electric vehicle prices to the overall sustainability of battery technologies. Companies in the energy and automotive sectors are particularly eager to watch how these developments unfold.

Call for Industry Adoption

The success of Stanford’s lithium extraction breakthrough depends on industry acceptance and implementation. Stakeholders across various sectors must be willing to invest in these new technologies to realize the full benefits of cleaner lithium extraction. Collaboration between research institutions, technology developers, and environmental advocates is essential to establish this method as the new standard in lithium production. The promise of a more sustainable future hinges on our ability to adopt and support innovations that prioritize both environmental health and economic viability.