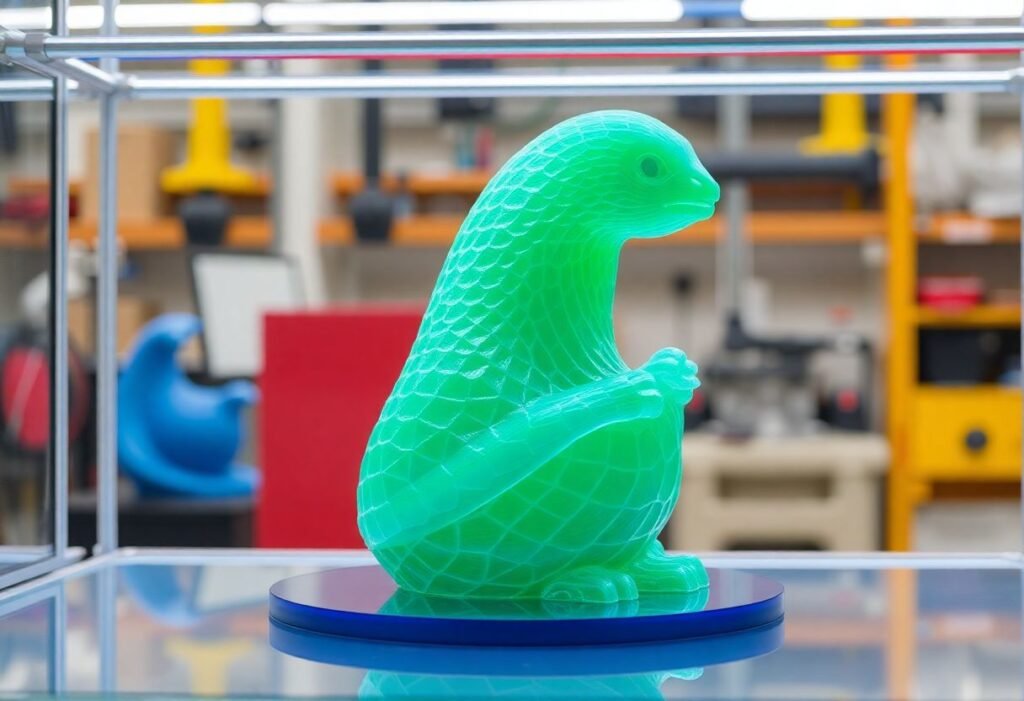

3D printing is revolutionizing traditional manufacturing by offering innovative solutions that enhance efficiency, reduce costs, and transform the design process. As industries adapt to a digital age, the role of additive manufacturing has become increasingly significant.

The Rise of 3D Printing in Manufacturing

3D printing, or additive manufacturing, has witnessed remarkable growth over the past decade. Its ability to create complex structures directly from digital models allows manufacturers to move away from traditional subtractive methods. This innovation not only reduces material waste but also allows for rapid prototyping, significantly accelerating product development cycles. According to recent studies, companies utilizing 3D printing exhibit a 30% reduction in costs within the first year of implementation. As a result, businesses are embracing this technology to stay competitive in the market.

Cost-Efficiency and Material Savings

One of the most compelling advantages of 3D printing is its ability to lower production costs. By minimizing material waste and expediting manufacturing processes, businesses can allocate budgets more effectively. Furthermore, the use of diverse materials, including metals, plastics, and bio-materials, allows manufacturers to innovate without sacrificing quality. For example, companies can produce complex geometries that were previously impossible, optimizing weight and enhancing performance while saving on raw materials.

Customization and Design Flexibility

In a highly competitive market, the ability to offer customized solutions is invaluable. 3D printing enables manufacturers to adapt designs for specific user needs quickly. With the design flexibility that additive manufacturing provides, businesses can produce unique products without incurring substantial costs. This has led to a surge in consumer demand for personalized goods, as customers seek one-of-a-kind solutions tailored to their preferences.

Impact on Supply Chain Management

3D printing is reshaping supply chains by allowing on-demand production. This diminishes the need for extensive inventory storage, which can be costly. By leveraging localized production capabilities, companies can shorten lead times and respond more swiftly to market changes. This strategic shift not only streamlines logistics but also reduces overhead costs associated with transportation and storage, enhancing overall supply chain efficiency.

Environmental Considerations

The sustainability factor associated with 3D printing is gaining traction, as it typically consumes less energy compared to conventional manufacturing. Additionally, the reduced waste from additive manufacturing contributes positively to environmental conservation. Companies committed to a sustainable manufacturing approach can leverage this technology to meet their eco-friendly goals while maximizing efficiency. In fact, studies indicate that industries adopting 3D printing sometimes report a reduction in carbon emissions due to decreased production cycles.

The Future of 3D Printing Innovation

As technology advances, the future of 3D printing is bright. Ongoing research in materials science, design software, and printing techniques will undoubtedly yield further innovations. With the advent of AI and robotics, the integration of these technologies with 3D printing will revolutionize traditional manufacturing dynamics. As global industries embrace these changes, the impact on innovation will be profound and far-reaching.

Disclaimer: This article is for informational purposes only and does not constitute professional advice.